Rotational moulding

Rotational moulding is currently used primarily for the production of fuel tanks and other tanks for liquids. Plastic powder is melted inside a mould in this process. Rotating the mould distributes the material across the mould. The mould determines the outside contour of the product. The inside is not shaped by the mould.

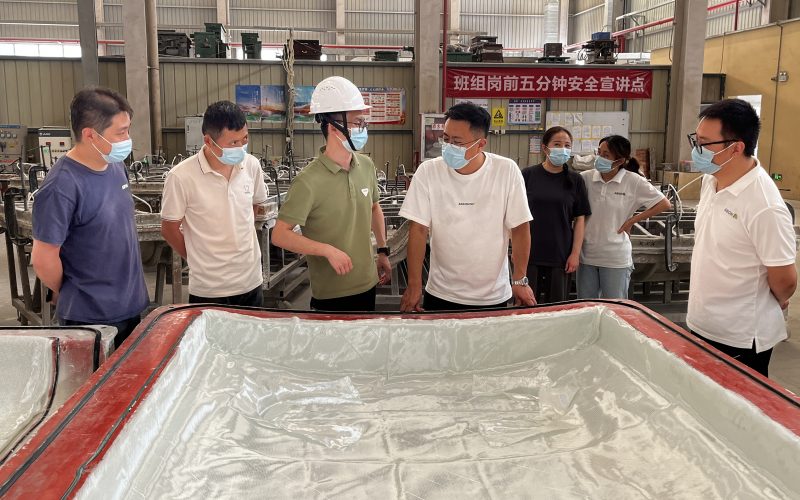

RTM

We frequently use Resin Transfer Moulding (RTM) to produce parts from fibre-reinforced plastics. For example, body parts or frames on the basis of polyurethane and an epoxy resin. A closed mould is used in the RTM process, resulting in a clean surface on both sides of the part. Plastic products produced in the RTM process are cut robotically and, if necessary, hole patterns are cut using laser cutters.

Hand lamination

Hand lamination - also called hand lay-up - is a technique that we generally use to produce complex shapes in small runs; for example, engine covers and decorative panels. An open mould is filled with polyester until the desired thickness is reached. After the first colour coat, several layers of glass fibre mat are placed in the mould and impregnated with resin. Then all the air is forced out using a roller.

Gel coating

We often use gel coats for our polyester components. Because this base material is coloured, the finished products are coloured through and through. The gel coat protects them effectively against weathering and any superficial damage is not immediately visible. In addition, the material is easy to clean and maintain.

Injection moulding

Plastic injection moulding is a manufacturing process that we use for large-scale production of identical plastic products. In plastic injection moulding, thermoplastic polymers in pellet form are melted and injected into a mould under high pressure. We frequently use this technique to produce clamps, for example.

Other processing operations

Metalworking

We offer you an extensive range of services that include (robotic) welding, broaching, levelling, deburring, laser cutting, water cutting and 3D bending.

Surface treatment

We protect your parts against corrosion and rust or improve conductivity with various forms of surface treatment, such as galvanising, powder coating, KTL, wet painting and hardening.