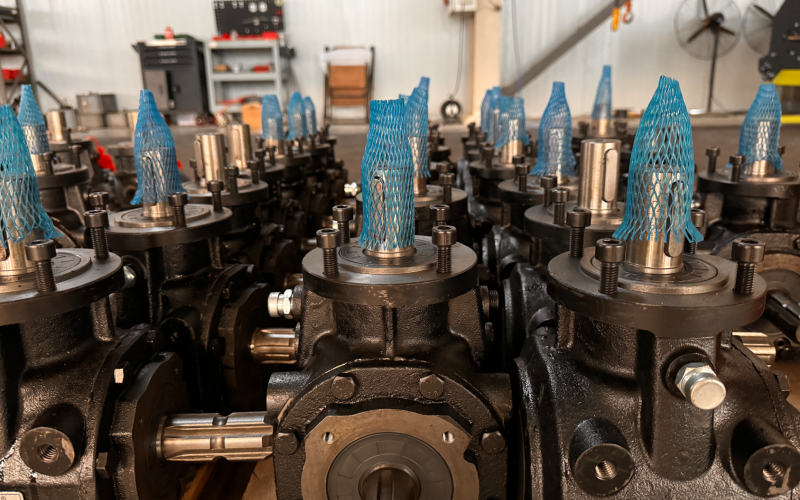

(Robotic) welding

Much welding work, especially small product runs, is done manually. Our certified welders perform this task every day. In our welding department, we also offer robotic welding for large runs of welded products. Thanks to our in-house toolmaking shop with 3D measuring equipment, we can always offer excellent results to a consistently high quality standard.

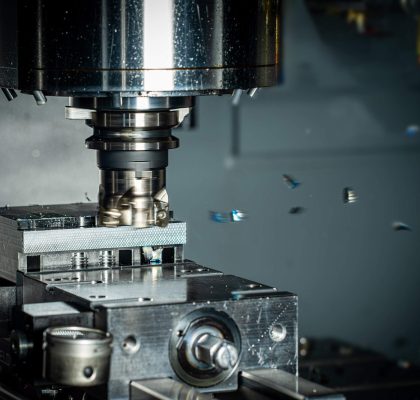

Broaching

Broaching is a machining technique in which the workpiece is fixed and the tool moves. We have developed our own broaching machines and guarantee machining to highly accurate tolerances to deliver the high quality you require. In addition to broaching, we can also offer you normal machining techniques, such as turning, milling and drilling.

Levelling and deburring

When it comes to levelling and deburring, we can also offer you the best of the best, thanks in part to our collaboration with ARKU, which specialises in precision levelling and innovative deburring technology. One of the four global ARKU Metal Levelling & Deburring Centers is located in close proximity to our production site. High-quality service, just around the corner from us.

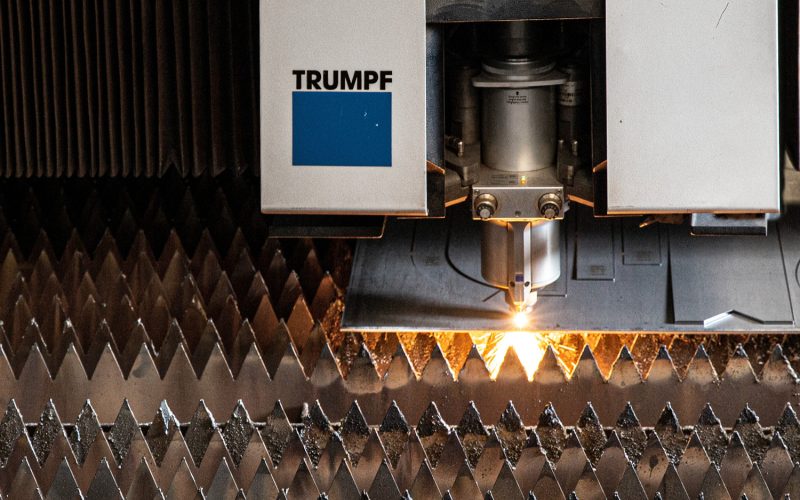

Laser cutting and water cutting

For laser cutting, we frequently use TRUMPF TruLaser 3000 and 5000 series machines. This means that we can laser cut up to a thickness of 25 mm. Above that thickness, we use water cutting machines.

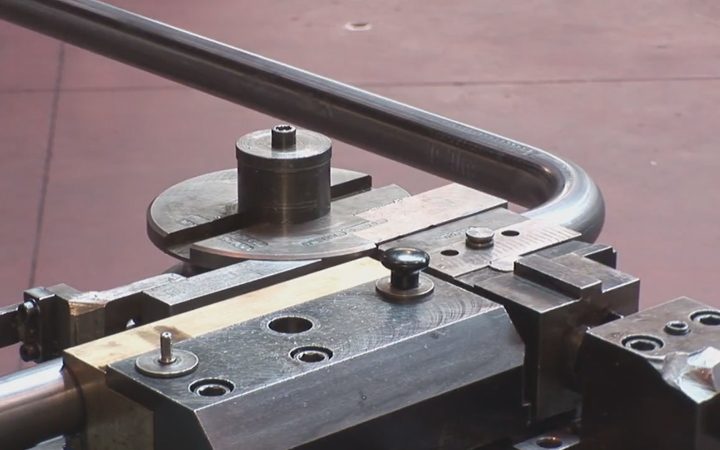

3D bending

Our engineers are at your disposal to design your 3D profiles, after which production is assigned to one of our specialised manufacturing partners. We then incorporate the 3D profile into your welded assembly. This is how we produce safe roofs that meet roof crush performance standards and cabs, among other items.

Other processing operations

Plastic processing

More and more machine components are made from synthetic materials, such as plastic and polyester. You can come to us for rotational moulding, RTM, hand lamination, gel coating and injection moulding.

Surface treatment

We protect your parts against corrosion and rust or improve conductivity with various forms of surface treatment, such as galvanising, powder coating, KTL, wet painting and hardening.